X Marks the Scot - An on-line community of kilt wearers.

|

-

4th February 06, 10:57 AM

#15

Adding the bolster

Well, it's raining, snowing, and blowing outside so what better time for the second installment of the build-along! I'll have to cut this post into two to get the photos to load.

Next we must add a bolster. Some blades come with a round tang and no flare at the butt of the blade, so this step is not necessary. The blades I'm using have bolster notches, so we'll add a metal bolster.

Custom knifemakers will use brass, bronze, silver, stainless steel, etc. for the bolster. Remember that we're making a "common man's" sgian, so I'm using aluminum. It works easily with files and paper, is cheap, and has that satin silver look to go with my blades. I picked up a 3' piece of 2" x 1/8" flat aluminum at the home store for $4. What doesn't get used for this project will make a dandy straight edge.

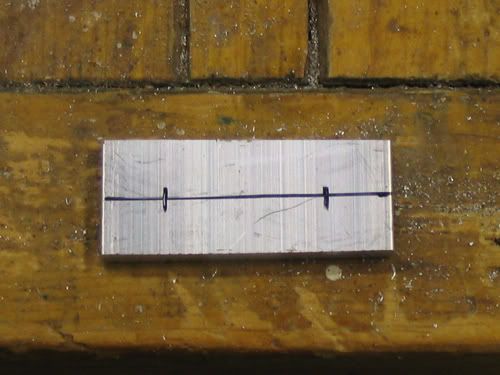

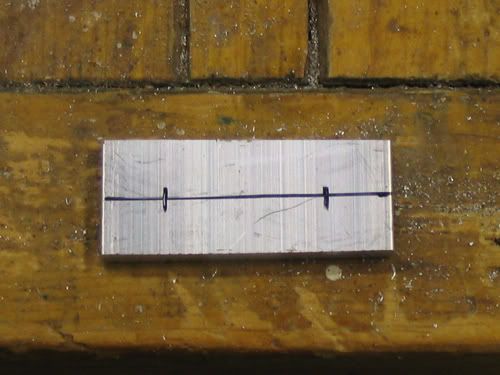

Cut a piece of material that is wider than you need in each dimension. My piece turned out to be 1.5" x 5/8 ". Mark the center line, then mark where the shoulders of the notches fall.

-

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

|

Bookmarks